Menu

Input your search keywords and press Enter

The documentation for the system begins before the first drawing is generated or the first welding arc is struck. Procurement, welding, assembly, testing, and automation, documentation is always kept in mind at all stages. Material traceability is established with the purchase and receipt inspection of materials and is systematically maintained throughout the Factory testing pro-manufacturing and assembly processes.

During the fabrication of equipment, various processes take place. We use different methods to document the designing, fabrication, assembling, and testing of the equipment. These include: Borescope inspection, video capabilities, Software design specification (as required), Factory testing procedures, Inspection records, Master inspection traveller, and Weld records.

The resulting turnover package provides a well-organized and comprehensive validation reference that parallels customer protocols. In addition to the standard three-ring binders, packages are also provided in CD/DVD formats.

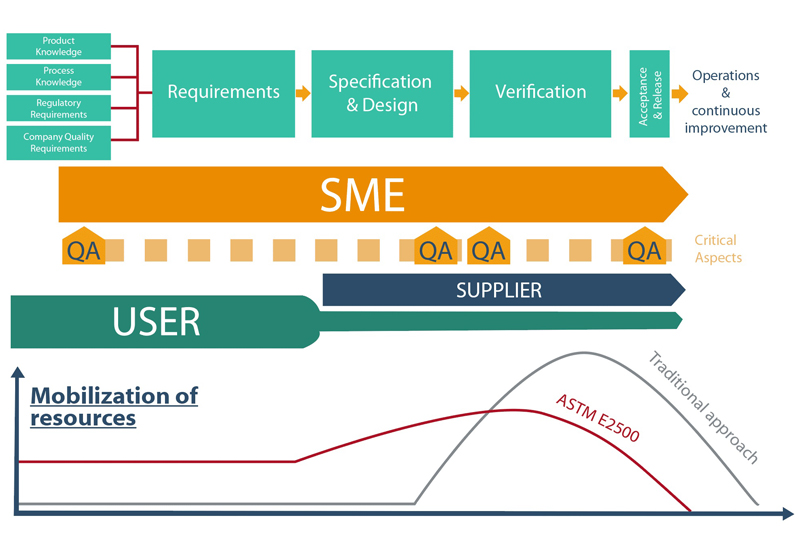

American Society for Testing and Materials or ASTM E2500 is a standard that goes way beyond verification or just testing. Driven by solid anticipation of the design and specification, this approach covers the entire project and involves all players from the very start of the project.

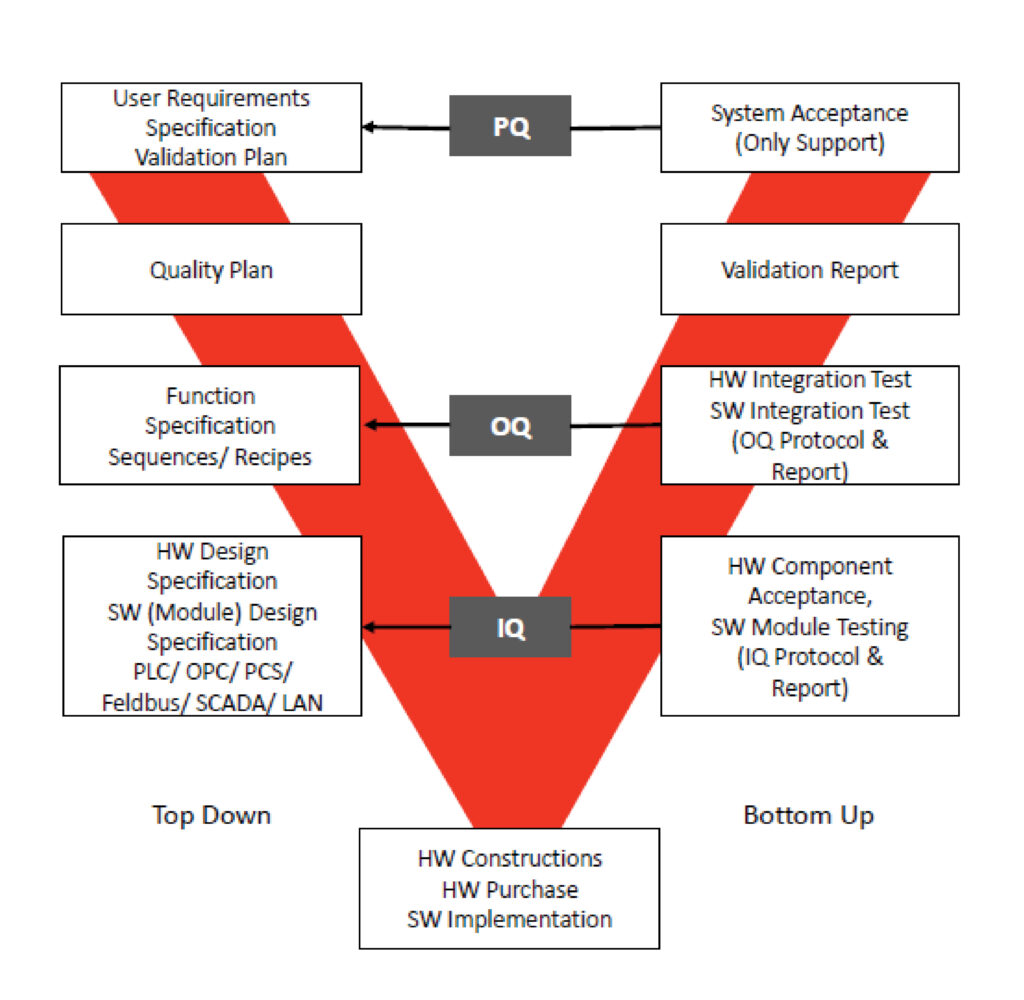

ASTM E2500(1) presents a number of similarities with the traditional V-model process, from the definition of needs through to the maintenance of the validated status.

The major innovation in this ASTM E2500 text lies in the fact that the tests to be carried out no longer follow a rigid FAT/SAT/IQ/OQ/PQ sequence as described in EU GMP Annex 15. All these tests brought together under the single term “Verification”, can now be more freely and rationally organized to optimize efficiency and be adapted to each context.

Qualifications

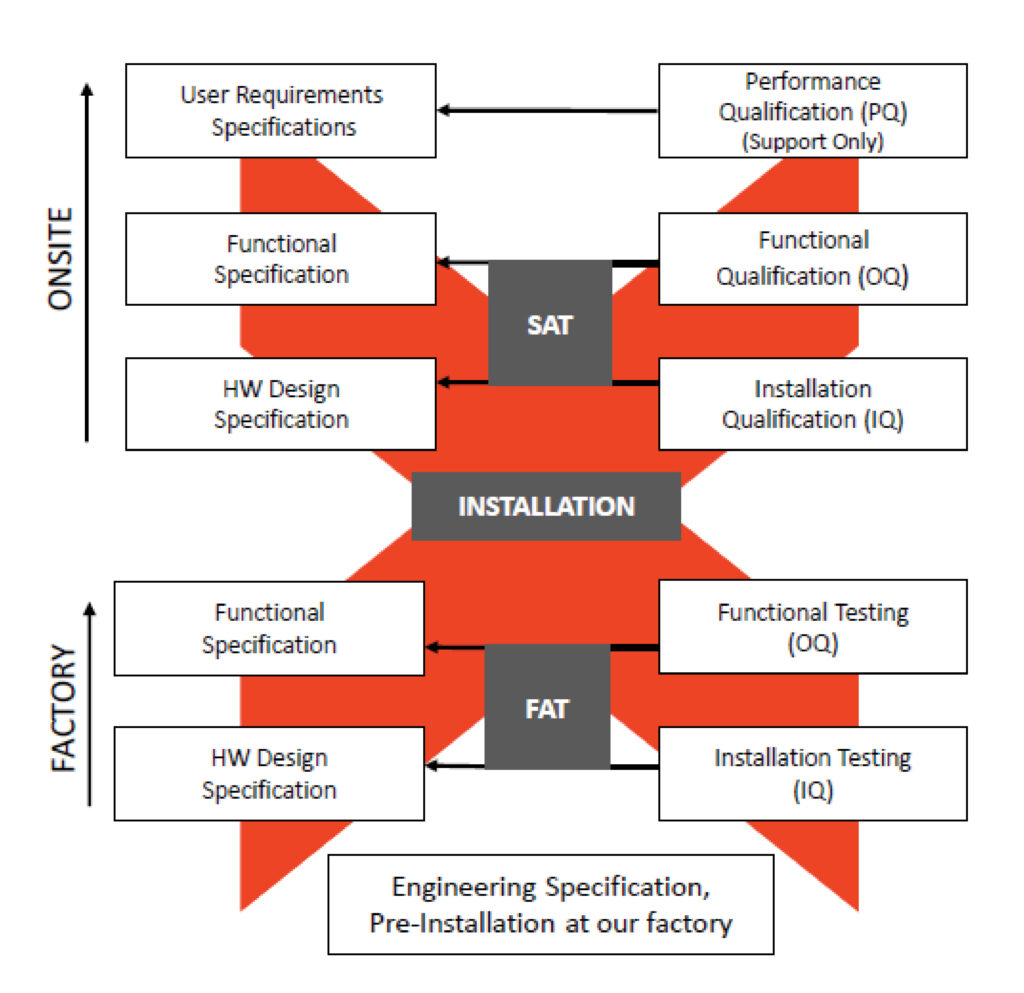

We use a qualification documentation system to monitor commissioning tests (FAT-SAT), optimize non-conformity management, facilitate and speed up reporting processes (review workflow, protocol approval, reports), standardized test protocols.

Automation

Some of the best automation engineers of the world work here in one of the leading manufacturers of bioreactors and fermenters, T3AM. All of our services comply with 21 CFR (part 11), GAMP V, and ANSI/ISA-88 standards.

Validation

A well-planned, documented and a managed engineering approach is used resulting in a safe and functional environment to meet established design requirements and stakeholder's expectations.

We use a qualification documentation system to monitor commissioning tests (FAT-SAT), optimize non-conformity management, facilitate and speed up reporting processes (review workflow, protocol approval, reports), standardized test protocols.

Some of the best automation engineers of the world work here in one of the leading manufacturers of bioreactors and fermenters, T3AM. All of our services comply with 21 CFR (part 11), GAMP V, and ANSI/ISA-88 standards.

A well-planned, documented and a managed engineering approach is used resulting in a safe and functional environment to meet established design requirements and stakeholder’s expectations.

Input your search keywords and press Enter.

WhatsApp us